Home » Products » Automatic Stirrup Bending Machine » Cnc Steel Wire Bending Machine Develop NO.5

Brand: PHMTOOLS

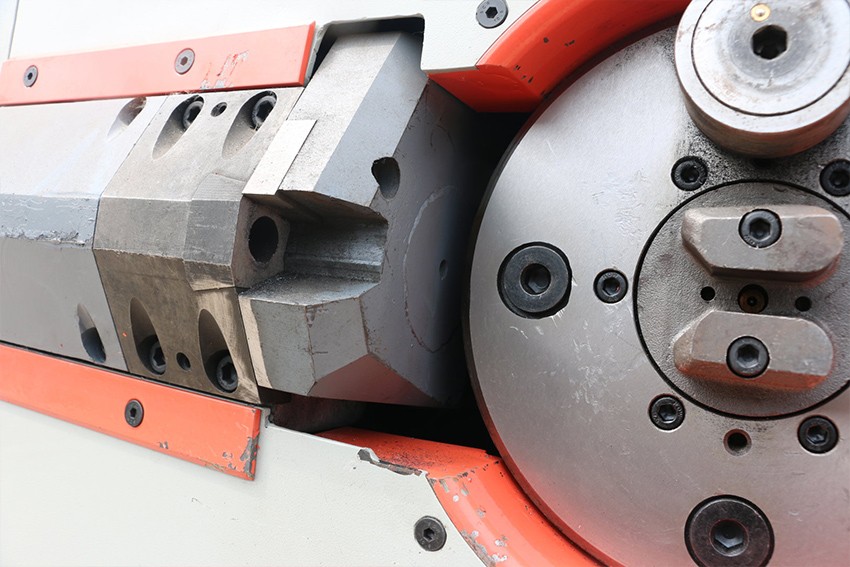

Size of Host Machine: 3560*1080*2030mm

Model: Develop No.5

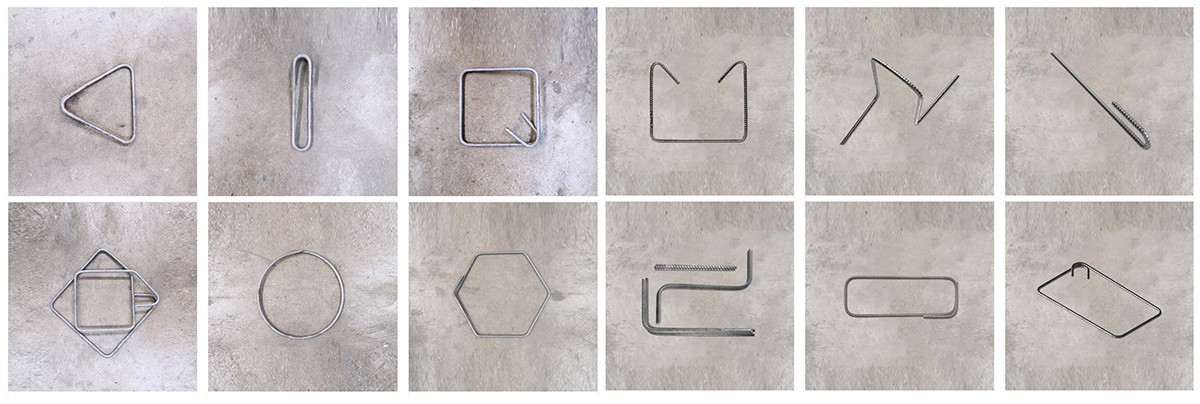

Cnc wire bending machines it is integrated steel processing equipment with straightening, bending and cutting functions. Therefore, steel bars can be processed into various angles and radius used to construction, such as triangle, quadrangle, pentagram, ring, many other polygons, etc.

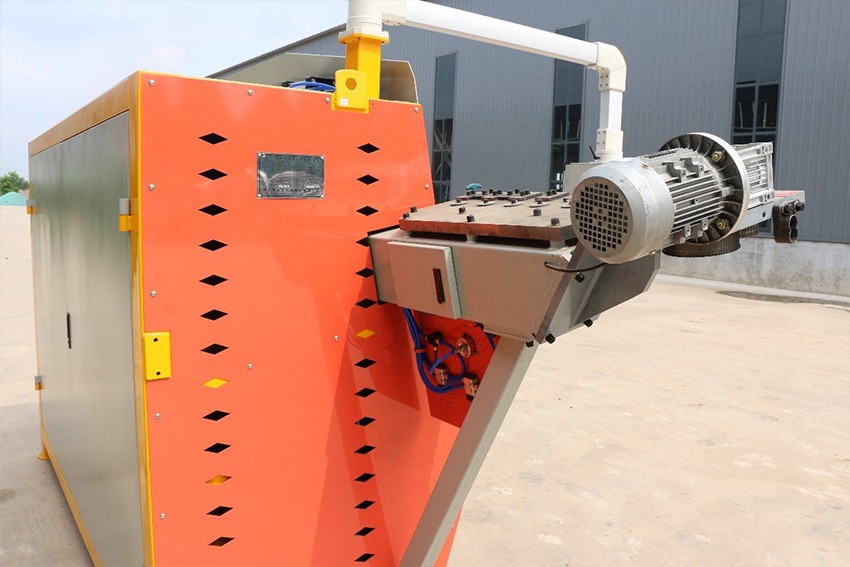

2023 latest Automatic Stirrup Bending Machine is an extension of the steel bending machine duo to its multi-functions. It is integrated steel processing equipment with straightening, bending and cutting functions. Therefore, steel bars can be processed into various angles and radius used to construction, such as triangle, quadrangle, pentagram, ring, many other polygons, etc. Our PHMTOOLS Automatic stirrup bending machine for sale is very popular with our clients at home and abroad for its features of high efficiency, precise cutting, fast speed and low price with high quality.

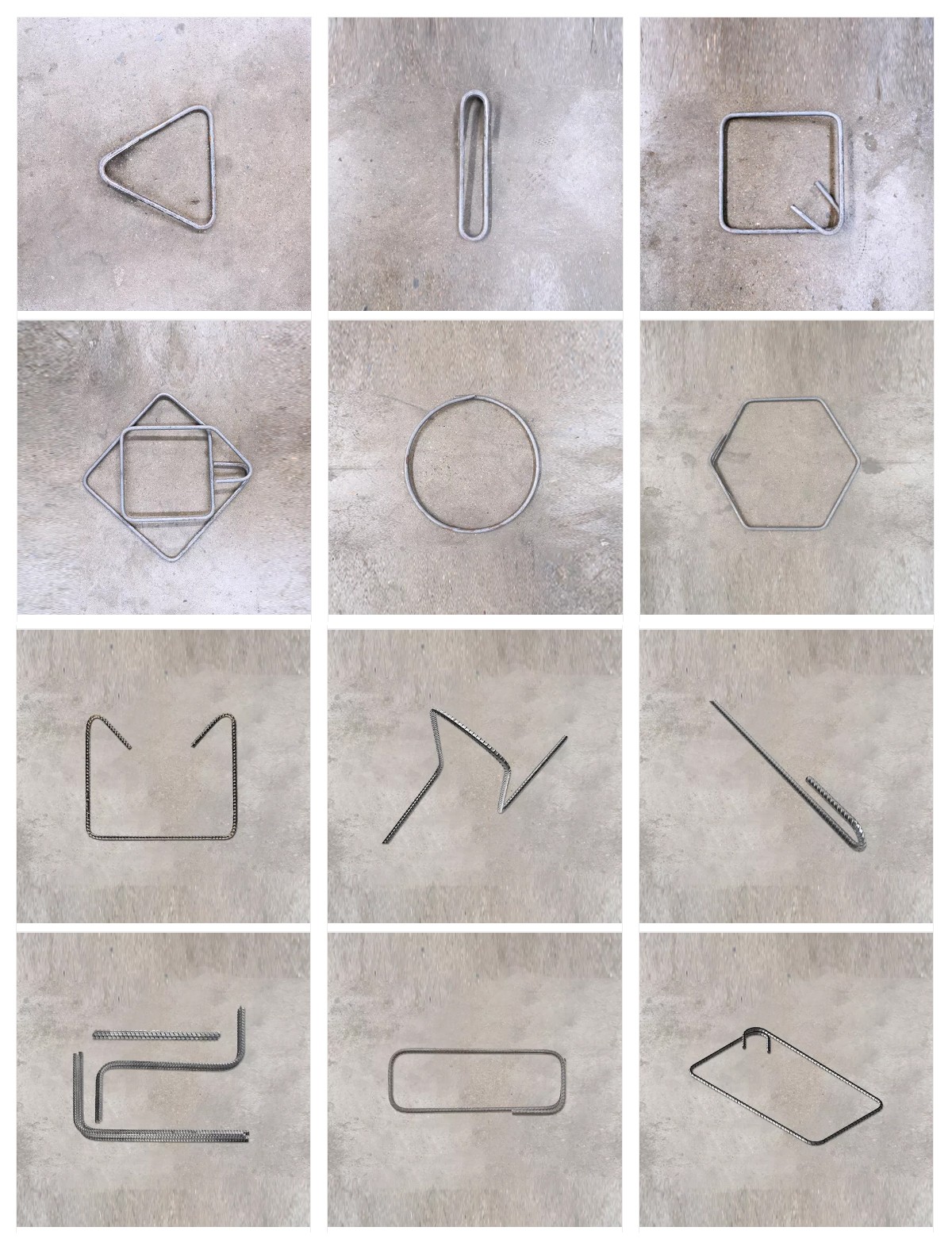

1. The special structure design, easy to deal with ribbed bars straightening, straightening ribbed bar does not injury.

2. Curve reinforcing bar staightening mechanism improves the straightening effect of steel bar and prevents the axial torsion of reinforcing bar.

3. Vertical straightening mechanism, each steel bar can be individually straightened to ensure the straightening quality of the steel bar.

4. All roller are made of high quality alloy steel, high hardness, good wear resistance, improved service life.

5. Close to the corner of the steel molding machine to control the steel bar, in order to ensure the quality of bending.

| Technical Specifications | |||

|---|---|---|---|

| Single Wire(mm): | Φ5-14mm Round Bar /5-14 Rebar | Pieces Processed: | ≤2 |

| Double Wire(mm): | Φ5-10mm Round Bar /5-10 Rebar | Power Equipment: | 30.5kw |

| Max Bending Angle: | ±180° | Steel Processing Shape: | 500 Types |

| Maximum Towing Speed: | 75m/min | Working Temperature: | -5℃~40℃ |

| Maximum Bending Speed: | 1000°/sec | Total Weight: | 2450KG |

| Length Accuracy: | ±1mm | Size Of Host Machine: | 3560*1080*2030mm |

| Average Power: | 5kw/h | Device Color: | Customized |

| Maximum Length Of Stirrup Side: | 1500mm | Minimum Length Of Stirrup Side: | 50mm |

The machine can handle rebar with diameters ranging from 4mm to 16mm, and for double lines, diameters from 4mm to 12mm. Its maximum bending angle is 180°. It can process rebar with a maximum size of 1.5 meters for bending. The product’s processing error does not exceed 0.5mm.

The machine processes one rebar hoop in 1.5 seconds, with a maximum traction speed of 110m/min. It can produce between 1900 to 2500 units (double wire) per hour, showcasing a rapid processing speed. One machine can replace the work of 30 manual laborers, saving up to $600 in labor costs. Additionally, it comes with complimentary wire racks to prevent rebar twisting and an automatic material picking rack.

Yes, it’s capable of prefabricating. The machine comes with 500 preset shapes stored internally, and adjustments for length, width, and height can be made later as required.

Yes, the machine is equipped with plate bending functionality. It can bend various shapes such as hoops, plate rebar, stirrups, figure-eight rebar, irregular stirrups, spiral stirrups, and more. Its bidirectional bending feature allows for processing various irregular stirrups effectively. Moreover, it can handle nearly 500 different specifications of workpieces, offering versatility in production.

The machine utilizes roller straightening for precise straightening of rebar, ensuring accuracy in the final product. Rebar straightening is automated, streamlining the operation process.

Yes, the product comes with a lifetime warranty. During this period, if there are any material or process defects, and the spare parts are in normal working condition, we will provide on-site repair or remote debugging services.

Spare parts are available throughout the year. In the case of quality issues, we will send you the necessary spare parts. Lifetime free maintenance is provided, including shipping for fragile parts of the rebar bending machine.

Each machine includes installation and commissioning services, and we also provide English user manuals and instructional videos. The control panel can be customized to support multiple languages.

In terms of usability, the machine offers versatility and efficiency comparable to a five-headed machine. It excels in processing various types of rebar, including irregular stirrups and spiral stirrups, making it a suitable choice for tasks requiring precision and flexibility.

1. Supply item design, process design.

2. Help you to chose the fitest machine.

3. Making the machine according to your requirement.

1. Acceptance equipment together with you .

2. Help you to make the method statement and the details of the process.

1. Guarantee for a year.

2. Quality problem, we will sent you the accessories.

3. Free repair whole using life (without the freight and accessories charge).

If our product has met your expectations or benefited your friend’s business, feel free to share the love! Relationships thrive on positive value exchange. Selfless sharing fosters collective growth. Thank you for being part of our journey.

Receive our monthly newsletter to stay current on all penghao innovations