Machines and equipment for the construction engineering, steel bar and fastener industries.

Machines and equipment for the construction engineering, steel bar and fastener industries.

We are a comprehensive enterprise integrating R&D, design, manufacturing, sales, and service. PHMTOOLS has more than 10 years of experience in manufacturing steel bar machinery and standard parts, such as bending machine series, thread rolling machine series, and construction site machinery.

It has been distributed all over the country and sold to overseas markets such as Southeast Asia, South Asia, Europe, North Africa, and the Middle East, and has established agents in Sri Lanka and Algeria. PHMTOOLS has won praise from customers. The speed of the hoop bending machine can reach 3000 pieces/hour, and the accuracy of the thread rolling machine is not higher than 0.02.

Automatic stirrup bending machine, thread rolling machine, steel bar reducing machine, straightening and cutting machine and other construction engineering machinery.

Integrated steel processing equipment with straightening, bending and cutting functions. Therefore, steel bars can be processed into various angles and radii for construction, such as triangles, quadrilaterals, pentagons, rings, and many other polygonal shapes, etc.

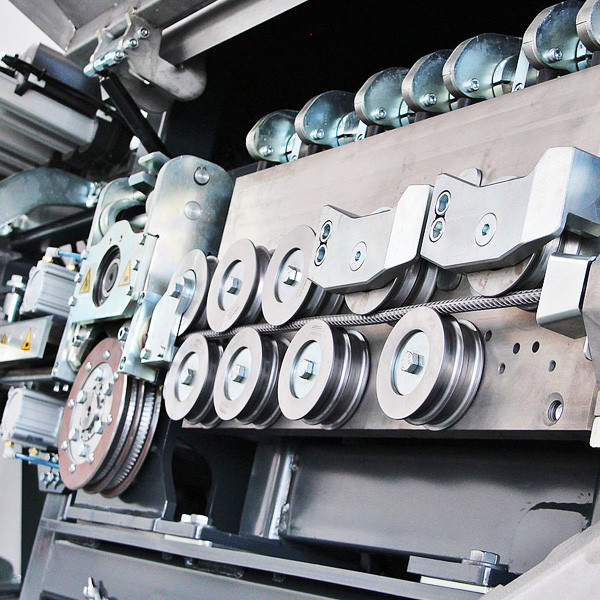

Thread rolling machineUsed for making thread on bolts, screws, fasteners, threaded rods Can be designed with antomatic feeding device Control panel easy to operate simple and convenient. Customized bolts such as rolled vertical thread and wheat ear pattern can be made.

Want to improve the efficiency and quality of building construction? Our construction site machinery is the perfect solution. Elevate your projects, increase productivity and achieve success with our comprehensive line of construction machinery.

• This type suitable for 4-12mm steel bar.

• It can process floor ribs.

• Various custom graphics.

• Bidirectional bending, with automatic feeding device.

• The most cost-effective model.

• Suitable for 4-12mm steel bar.

• Won the championship for three consecutive years and can process 200 kinds of graphics.

• The fastest working efficiency: 1 workpiece / 20 s.

• Maximum workpiece length: Unlimited.

At PHMTOOLS, we pride ourselves on offering free pre-sales consultation to our valued customers. Please feel free to contact our professional pre-sales consultants. We are committed to providing you with the most appropriate and cost-effective solution based on your processing requirements. Your success starts with PHMTOOLS.

PHMTOOLS

Our experienced PHMTOOLS team has a decade of industry expertise and is dedicated to understanding your unique needs. We specialize in steel bar bending machine series, thread rolling machine series and construction site machinery. Trust PHMTOOLS to guide you in choosing the most appropriate and cost-effective machine, ensuring your project thrives with precision and efficiency.

PHMTOOLS

At PHMTOOLS, our professional services team is dedicated to making sure you’re satisfied with us. We provide comprehensive online and offline after-sales assistance and remotely guide you through machine operation and maintenance. If necessary, our experts are always ready to arrive on site and solve the problem immediately.

PHMTOOLS

PHMTOOLS has provided construction engineering machinery solutions to more than 200 users to meet customers’ different processing needs. Here are some customer feedback and experiences.

United States Construction Projects

Mexican Construction Company

French Steel Manufacturing Workshop

You can get more machine related knowledge from our blog.

Add lubricating oil to the lubricating point, keep the workbench and the bending machine table level, and prepare various mandrel tool stops, and start the machine after confirming that it is normal.

Lubricating oil should be added before installing and using the steel bar hoop bending machine, and check whether the screws of the whole machine and electrical appliances are loose or damaged during transportation.

The global construction industry relies on a diverse array of machinery to ensure efficiency, precision, and productivity. In this article, we’ll explore 14 common types of construction machines that are readily available on a global scale:

Automatic rebar bender and cutter machines are essential tools in the construction industry. To ensure the longevity and optimal performance of these machines, regular maintenance is crucial.

As the demand for robust and reliable rebar processing solutions continues to grow, selecting the right steel rebar bender becomes paramount.

PHMTOOLS stands out with over a decade of expertise in manufacturing steel reinforcement machinery. Our products, including bending machines and thread rolling machines, are known for their high efficiency and precision. We have a strong nationwide presence in China and a successful track record in international markets, earning accolades from satisfied clients.

PHMTOOLS distinguishes itself through a combination of robust company strength, top-notch products, comprehensive after-sales service, and a diverse product range. Our commitment to quality and customer satisfaction has made us a preferred choice for distributors.

Purchasing from PHMTOOLS is a straightforward process. You can explore our product catalog, contact our sales team for detailed information, and receive assistance in choosing the right machinery for your needs. Our efficient sales and support teams ensure a smooth transaction from inquiry to delivery.

PHMTOOLS provides a range of after-sales support, including permanent warranty, spare parts for any quality issues, lifetime free maintenance (excluding freight and spare parts fees), and free delivery of wearing parts of the steel bar bending machine. Also if a material or workmanship defect occurs and the spare part is in normal working order, we will come to repair/remotely debug it. Our commitment is not just to sell a machine, but to ensure its continued performance and durability.

PHMTOOLS has a proven track record of delivering construction machinery solutions to over 200 clients. Whether your customers are looking for efficient bending machines or precise thread rolling machines, we offer tailored solutions to meet diverse processing requirements. Our reputation for quality products and reliable service can enhance your credibility as a distributor.

Receive our monthly newsletter to stay current on all penghao innovations