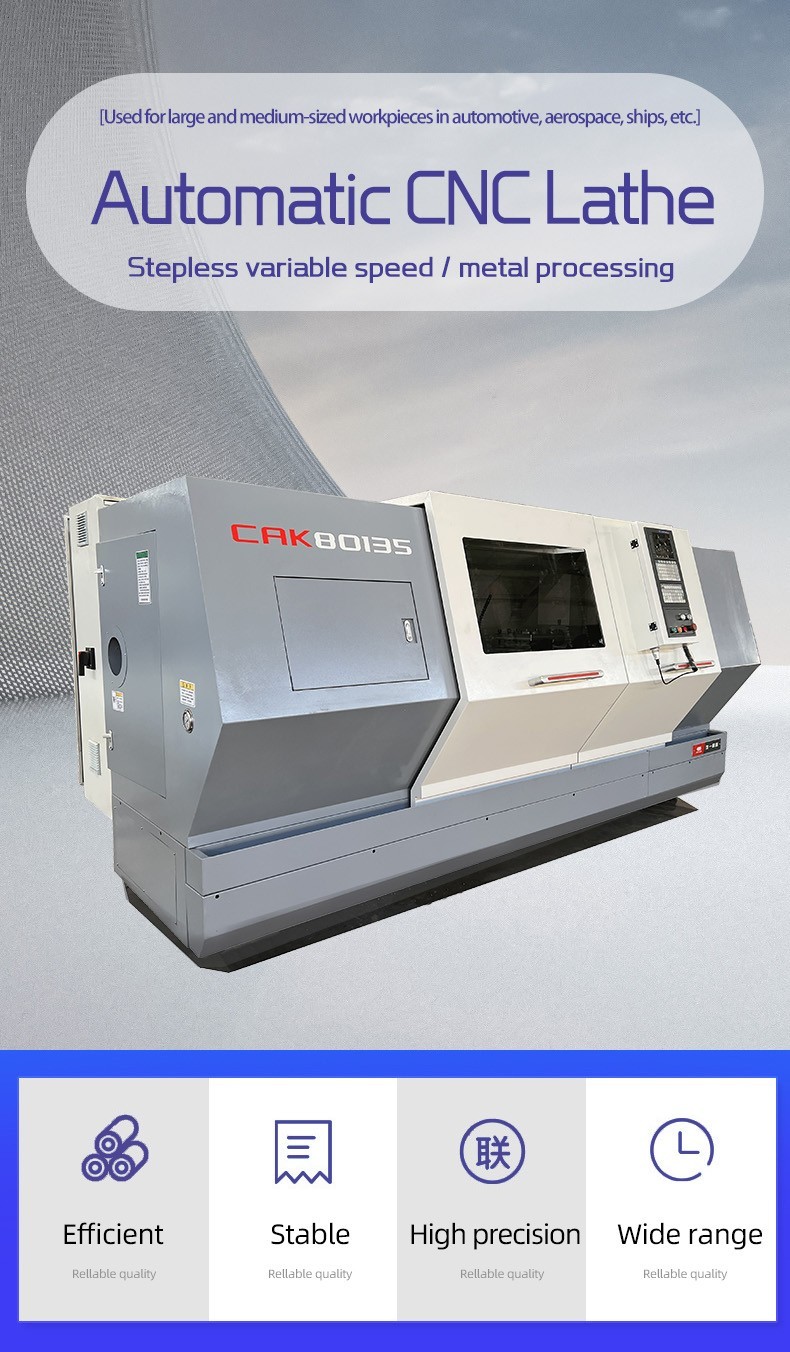

Home » Products » CNC Horizontal Lathe Machine » CNC Horizontal Lathe Machine CAK80135

The integral flat bed integral casting structure. Bed, bed, bed saddle, bed legs, etc. are found in resin sand casting, overall stability.

Model: CAK80135

1. The integral flat bed integral casting structure. Bed, bed, bed saddle, bed legs, etc. are found in resin sand casting, overall stability.

2. Bed guideline super audio quenching, bed down and skateboard guide bonding surface adopts “plastic” treatment, mobile components can realize trace feed to prevent crawling.

3. The feed system adopts servo motor, precision ball screw, high rigid precision composite bearing structure, accurate positioning, high transmission efficiency.

4. High spindle speed, wide speed range, low machine noise, main transmission four-speed variable speed converter motor to achieve mileging in the file.

5. The appearance protection design is novel and unique, waterproof, antiboda, convenient for maintenance.

6. The follow-up manipulation box is convenient for the operator to close the knife.

7. It is equipped with a centralized lubricator to enforce automatic lubrication of ball screws and angelica joint surfaces, which can effectively improve the dynamic response characteristics of the machine and the service life of the lead rail rail.

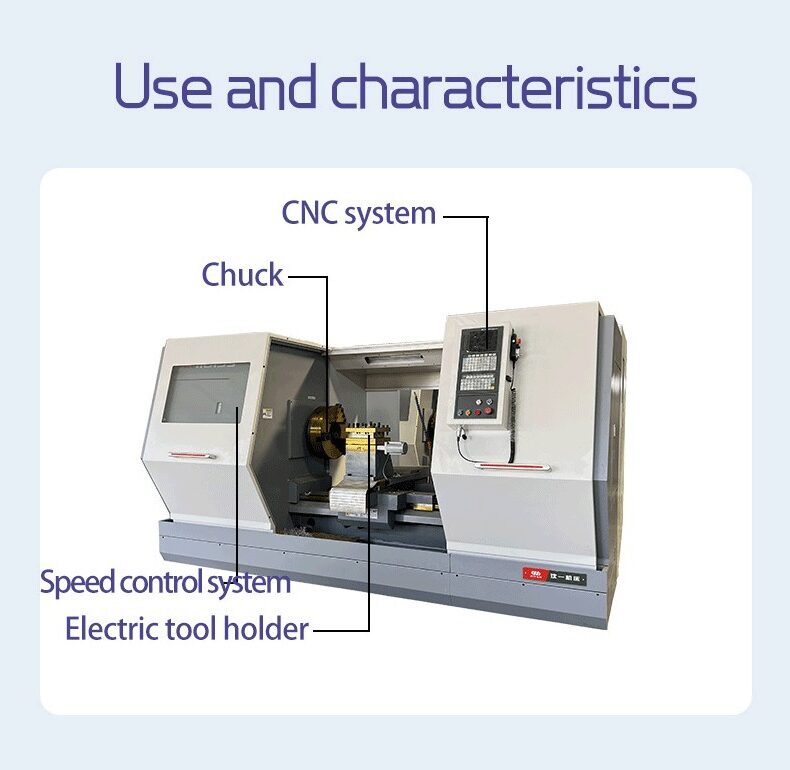

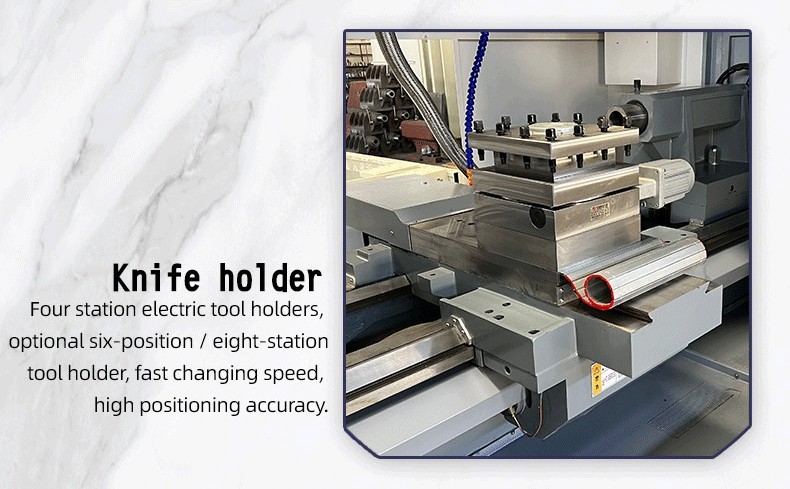

8. The tool holder has a vertical four-station, a vertical six- station, a horizontal six station, a quick cutting frame, etc.

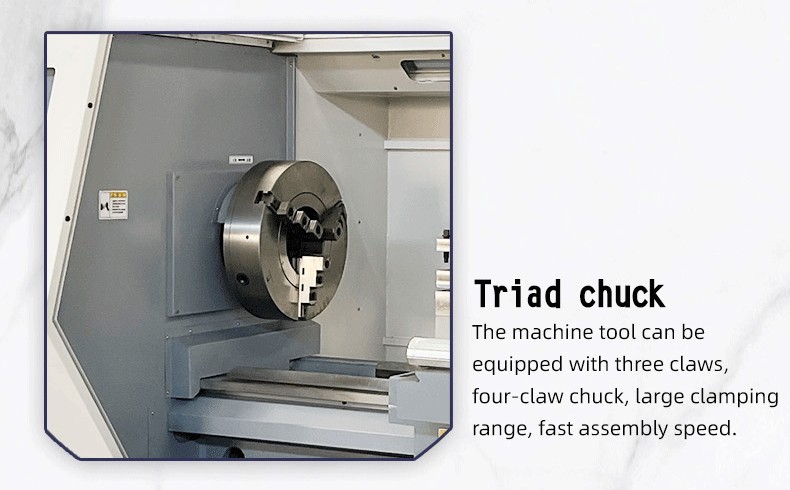

9. Accordling to user requirements, manual, pneumatic, hydraulic chuck manual, pneumatic, hydraulic tail seat.

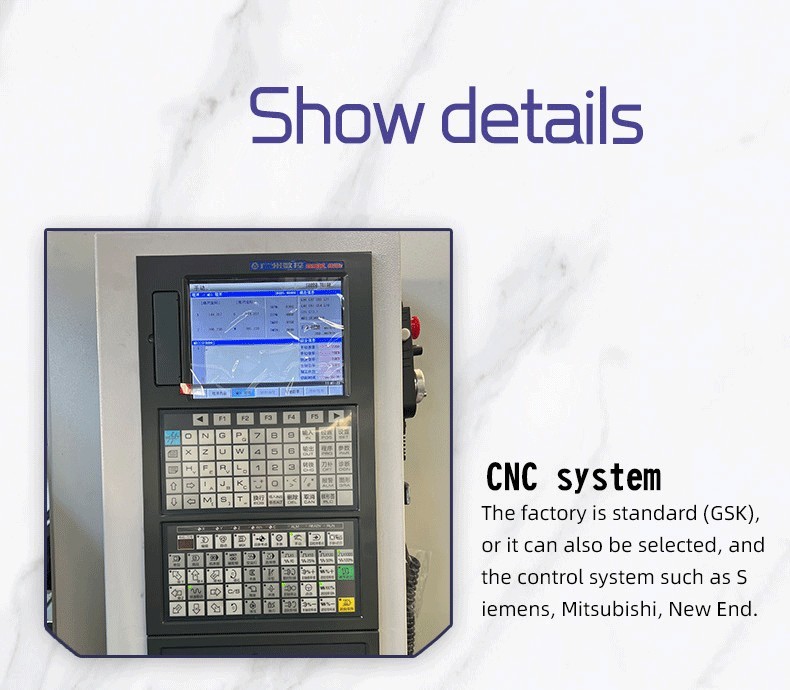

10. The control system has internationally renowned brands such as GSK, Fanuc, Siemens.

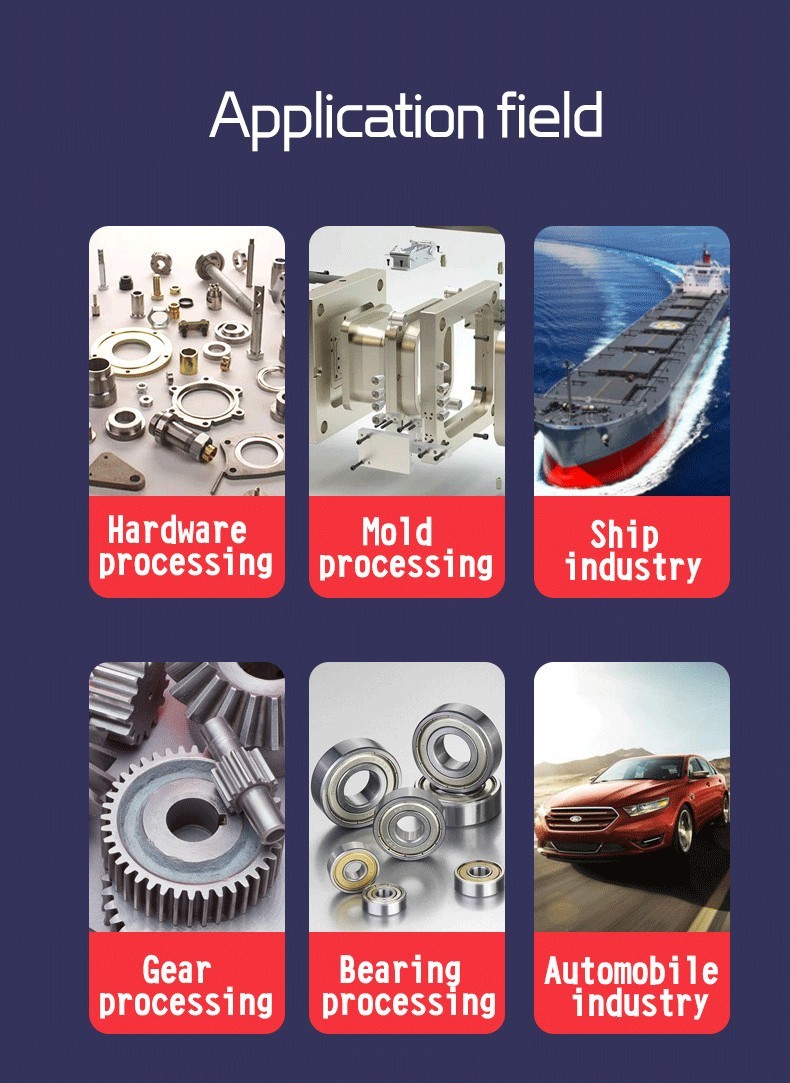

Automatic CNC lathe is an automated machine tool with a program control system, and a numerical control device is input by an information carrier, which solves the problem of complex, precision, small batch, and multi-variety.

The factory is standard(GSK), or it can also be selected, and the control system such as Siemens, Mitsubishi, New Wns.

Four station electric tool holders, optional six-position/eight-station tool holder, fast changing speed, high positioning accuracy.

The machine tool can be equipped with three claws, four-claw, large clamping range, fast assembly speed.

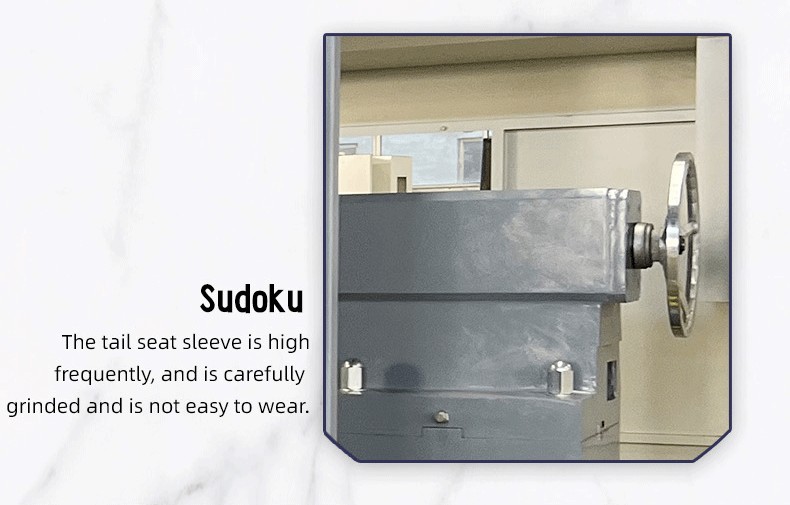

The tail seat sleeve is high frequently, and is carefully grinded and is not easy to wear.

1. Entity manufacturers, provide custom services.

2. Multiple models, welcome to factory test machine.

The machine can handle rebar with diameters ranging from 4mm to 16mm, and for double lines, diameters from 4mm to 12mm. Its maximum bending angle is 180°. It can process rebar with a maximum size of 1.5 meters for bending. The product’s processing error does not exceed 0.5mm.

The machine processes one rebar hoop in 1.5 seconds, with a maximum traction speed of 110m/min. It can produce between 1900 to 2500 units (double wire) per hour, showcasing a rapid processing speed. One machine can replace the work of 30 manual laborers, saving up to $600 in labor costs. Additionally, it comes with complimentary wire racks to prevent rebar twisting and an automatic material picking rack.

Yes, it’s capable of prefabricating. The machine comes with 500 preset shapes stored internally, and adjustments for length, width, and height can be made later as required.

Yes, the machine is equipped with plate bending functionality. It can bend various shapes such as hoops, plate rebar, stirrups, figure-eight rebar, irregular stirrups, spiral stirrups, and more. Its bidirectional bending feature allows for processing various irregular stirrups effectively. Moreover, it can handle nearly 500 different specifications of workpieces, offering versatility in production.

The machine utilizes roller straightening for precise straightening of rebar, ensuring accuracy in the final product. Rebar straightening is automated, streamlining the operation process.

Yes, the product comes with a lifetime warranty. During this period, if there are any material or process defects, and the spare parts are in normal working condition, we will provide on-site repair or remote debugging services.

Spare parts are available throughout the year. In the case of quality issues, we will send you the necessary spare parts. Lifetime free maintenance is provided, including shipping for fragile parts of the rebar bending machine.

Each machine includes installation and commissioning services, and we also provide English user manuals and instructional videos. The control panel can be customized to support multiple languages.

In terms of usability, the machine offers versatility and efficiency comparable to a five-headed machine. It excels in processing various types of rebar, including irregular stirrups and spiral stirrups, making it a suitable choice for tasks requiring precision and flexibility.

1. Supply item design, process design.

2. Help you to chose the fitest machine.

3. Making the machine according to your requirement.

1. Acceptance equipment together with you .

2. Help you to make the method statement and the details of the process.

1. Guarantee for a year.

2. Quality problem, we will sent you the accessories.

3. Free repair whole using life (without the freight and accessories charge).

If our product has met your expectations or benefited your friend’s business, feel free to share the love! Relationships thrive on positive value exchange. Selfless sharing fosters collective growth. Thank you for being part of our journey.

Receive our monthly newsletter to stay current on all penghao innovations