Client: USA Construction Firm

Challenge

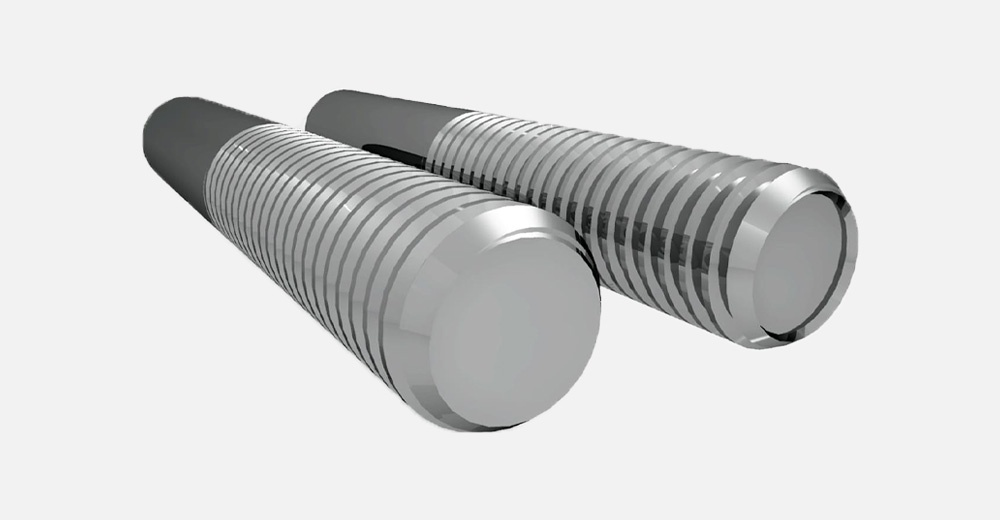

In the bustling construction landscape of the USA, a prominent construction firm faced a critical challenge in their high-rise projects. The need for precise threads on steel rods was paramount, yet traditional manual threading methods were proving to be inefficient and prone to inconsistencies. Meeting stringent construction standards demanded a revolutionary solution.

Solution

Recognizing the urgency of the situation, the construction firm turned to PHMTools for their state-of-the-art Thread Rolling Machine. Tailored to address the specific challenges faced in the USA’s construction industry, this machine promised a leap forward in threading accuracy. The advanced capabilities of the machine not only eliminated manual labor but also ensured uniform and accurate threads on steel rods.

PHMTools worked closely with the construction firm, customizing the Thread Rolling Machine to align seamlessly with the unique demands of high-rise construction in the USA. The machine’s versatility allowed it to adapt to various steel profiles commonly used in American construction projects, further solidifying its position as the go-to solution.

Outcome

The impact was transformative. The construction firm experienced a remarkable 40% reduction in threading time, translating to substantial time and cost savings. The precise threads achieved by the Thread Rolling Machine enhanced the structural integrity of their high-rise projects, earning them recognition for unparalleled craftsmanship in the competitive construction market of the USA.