Effective Maintenance: How to keep your rebar bending and cutting machine in top condition?

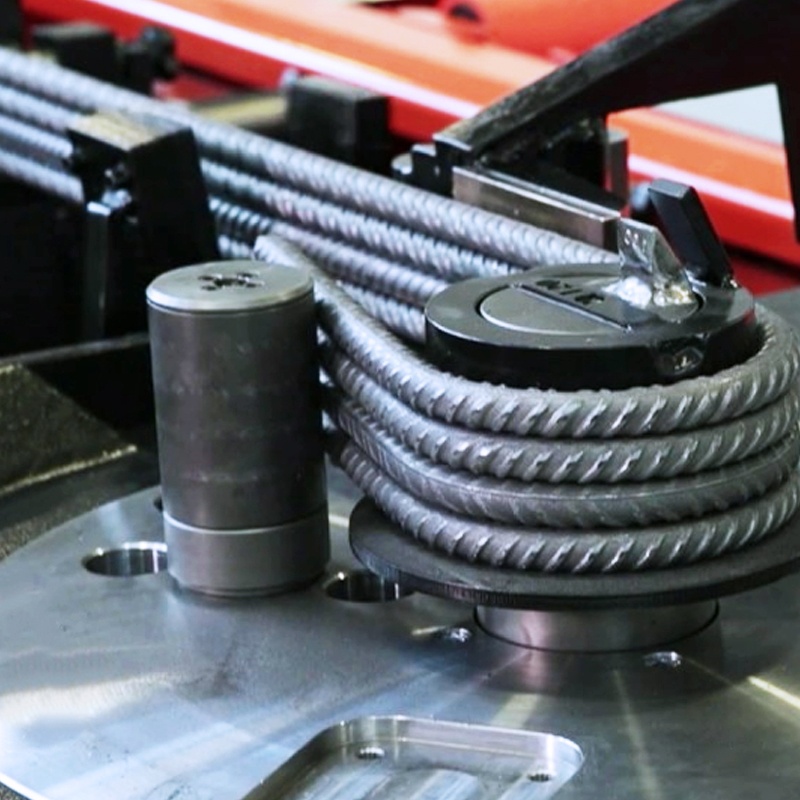

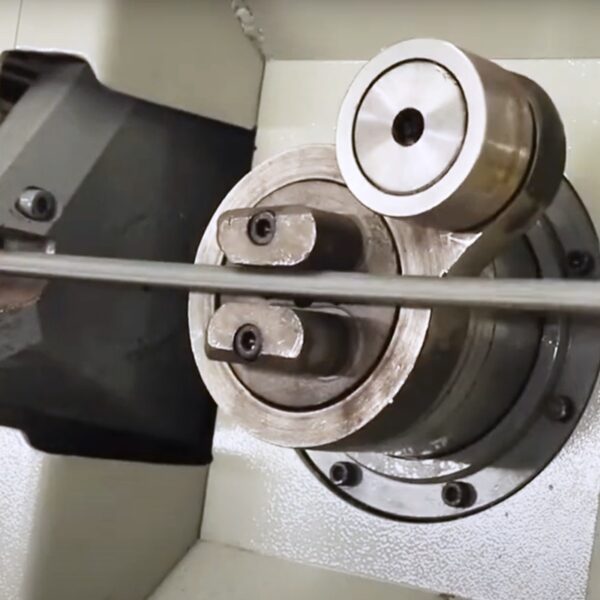

Automatic rebar bender and cutter machines, including CNC rebar bending machines and rebar stirrup bending machines, are essential tools in the construction industry. To ensure