14 Most Common Types Of Building Construction Equipment You Can Shop Worldwide

The global construction industry relies on a diverse array of machinery to ensure efficiency, precision, and productivity. In this article, we’ll explore 14 common types

Are you exploring construction machinery and equipment for engineering construction projects, steel processing, fastener manufacturing? Are you looking for a reliable source to buy brand new industrial construction machinery online in 2024 at competitive prices or consider buying used construction machinery from local stores or overseas manufacturers for road construction, civil construction, bridge construction, concrete Construction, house building, railway building, worksite use, commercial use, and industrial manufacturing?

Do you need customized online and offline steel bar processing services from local dealers or overseas manufacturers? Explore 2024 tailor-made for construction companies, steel processing engineers, manufacturing engineers, steel plant managers, quantity surveyors, factory managers, construction machinery and equipment manufacturers, agents, distributors, traders, wholesalers, and industrial manufacturers The ultimate buying guide. PHMTOOLS stands out as the most trusted destination for buying construction machinery and equipment in 2024.

Explore PHMTOOLS’s most affordable range of automatic stirrup bending machines, thread rolling machines, steel bar reducing machines, straightening and cutting machines, and other construction machinery. We offer a variety of products, including hoop bending machine series, thread rolling machine series, and construction site machinery.

PHMTOOLS offers 24/7 free expert customer service to ensure your business plans and ideas stay within budget. Find the perfect rebar processing solution for your business by exploring our extensive product range and taking advantage of our competitive pricing and dedicated customer support. Contact us online or visit our website to experience PHMTOOLS excellence in rebar machinery manufacturing and service.

The automatic stirrup bending machine is an extension of the steel bar bending machine and has versatility. It is a steel processing equipment that integrates straightening, bending and cutting functions. Therefore, steel bars can be processed into various angles and radii for construction, such as triangles, quadrilaterals, pentagons, rings, many other polygons, etc. The PHMTOOLS automatic stirrup bending machines we sell are very popular among domestic and foreign customers with the characteristics of high efficiency, precise cutting, fast speed, low price and good quality.

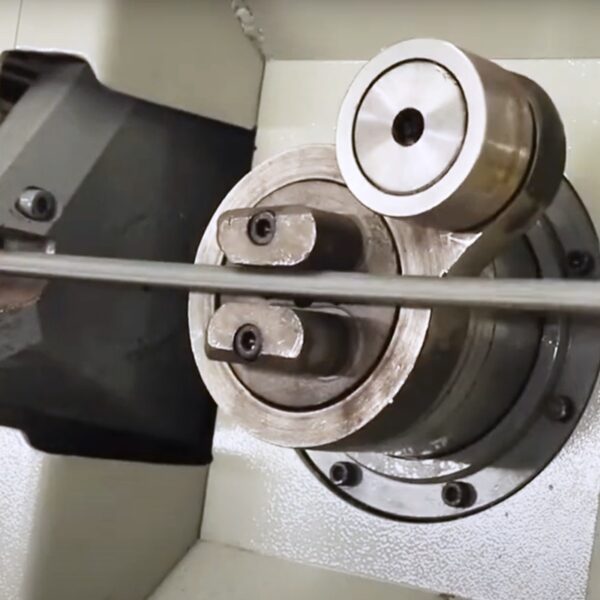

Our thread rolling machines are used for processing threads on bolts, screws, fasteners, threaded rods. Can be designed with automatic feeding device. It can perform radial or axial processing, and can process ordinary bolts, special bolts, tie rods, etc. with the corresponding rolling wheel. Robust construction enables deep thread forming, worm machining, grooving, knurling, rigidity and simplicity: hardened grade reduction and proper scrap sliding, easy adjustment of machine and tools allow unskilled workers to operate the machine. The machine is ideal for mass production and optimal surface finish.

A non-cutting processing machine with the advantages of efficient production, simple equipment, easy operation, saving of raw materials, and stable quality. It uses hydraulic technology to bring the required shrinkage parts such as round steel and rebar to special grinding tools for shrinkage molding, thereby increasing the density of the pressed steel and the tensile strength of the material.

It has functions such as preset, automatic counting, automatic parking, and steel bar guidance. Compared with similar products from other manufacturers, the straightening frame adopts hot rolling process and has the characteristics of beautiful appearance, strong rigidity and good straightening effect. The hydraulic system is simple, reliable and does not leak oil.

The global construction industry relies on a diverse array of machinery to ensure efficiency, precision, and productivity. In this article, we’ll explore 14 common types

Automatic rebar bender and cutter machines, including CNC rebar bending machines and rebar stirrup bending machines, are essential tools in the construction industry. To ensure

As the demand for robust and reliable rebar processing solutions continues to grow, selecting the right steel rebar bender becomes paramount.

There are 14 most common types of construction machinery, each with its own advantages and disadvantages for various processing techniques, including Automatic Stirrup Bending Machine, Steel Pipe Polishing Machine, Thread Rolling Machine, Reducing Diameter Machine, Straightening And Cutting Machine, Wire Drawing Machine, Manual Bending Machine And Cutting Machine, Roll Cage Welding Machine, Road Surface Construction Machine, Transfer Pump, Multi Blade Saw, Fog Cannon Gun, Cnc Horizontal Lathe Machine, Tower Crane. Additionally, types can be defined based on end use, functionality.

Divided into two types based on end use

Including machinery used in industrial building construction and bolt manufacturing, fastener processing machinery.

Divided into thirteen types according to function

Including straightening, bending, cutting, thread rolling, compression, straightening and cutting, wire drawing, steel pipe polishing, roll cage welding, conveying, dust suppression, precision machining, and heavy lifting.

Automatic stirrup bending machines are widely used to process steel into various shapes.

Steel pipe polishing machine is used to polish steel pipes to ensure that the surface of the steel pipes is smooth and clean.

Thread rolling machines play a vital role in processing threads on bolts, screws and rods.

Reducer The reducer is a non-cutting processing machine that can efficiently compress round steel and threaded parts to increase material density and tensile strength.

The straightening and cutting machine has functions such as preset, automatic counting, and steel guidance, making it an ideal choice for straightening and cutting steel.

Wire drawing machines are essential for reducing wire diameter and creating a smoother, more uniform surface.

Manual bending and cutting machines offer flexibility in bending and cutting steel, allowing for precise customization to construction project requirements.

The roll cage welding machine can automate the roll cage welding process.

Pavement construction machines are special equipment used for road construction and maintenance, ensuring that the road surface is smooth and durable.

Transfer pumps are essential for moving fluids such as concrete from one location to another on a construction site, thereby facilitating various construction processes.

Multi-blade saws are powerful cutting tools used for efficient and precise cutting of materials including wood, metal and concrete on construction sites.

Fog cannons are used on construction sites to suppress dust, improve safety and create a healthier working environment.

CNC horizontal lathes provide precision machining of a variety of components used in construction projects.

Tower cranes are iconic products in the construction industry, with heavy-duty lifting capabilities and the ability to place materials at high altitudes.

Automation

One machine replace 15 labors, one day can save 2000USD. Productivity is high, quite 20-30 artificial. The equipment use is strong, just one person operation, save a lot of artifical.

Versatility

The product range, including automatic stirrup bending machines, thread rolling machines, reducing diameter machines, and straightening and cutting machines, offers versatile solutions for various construction needs.

Innovative Features

PHMTOOLS construction machinery integrates advanced features, ensuring high precision, efficiency, and adaptability to diverse construction projects.

Safety Certificate

Creates a safe working environment that ensures products produced always meet quality control guidelines.

Robust After-Sales Support

Lifetime free maintenance with no shipping or parts fees. Complimentary delivery of vulnerable parts for steel bar bending machines.

Comprehensive Services

The offered services, including 24/7 support, on-site training, and installation, demonstrate a commitment to customer satisfaction and after-sales support.

1. Power on and set up:

First turn on the power. Make sure all safety precautions are in place.

Set machine parameters according to the specific requirements of the task.

2. Material loading:

Load the rebar or wire coil onto the machine’s feed mechanism and secure it properly.

3. Programming:

Enter the desired specifications for the finished product into the machine’s control panel. This includes the required angle, length, and any other parameters required for your specific design.

4. Machine calibration:

Calibrate the machine by running a test cycle using a piece of scrap material to ensure angles and dimensions match programmed values.

5. Start the bending process:

After successful calibration, start the machine.

6. Check:

Regularly inspect finished products for accuracy, quality and consistency. If necessary, adjust machine settings to meet required standards.

7. Continuous operation:

For batch production, reload materials as needed to keep the machine running continuously. Monitor operations to ensure consistent quality throughout the production process.

8. Maintenance:

Perform routine maintenance tasks to keep machines in top condition. This may include lubricating moving parts, checking for wear, and resolving any issues promptly.

9. Shut down:

After a production run is completed or when the machine is not in use, follow the manufacturer’s guidelines to shut down the machine. Power off the machine and clean the work space.

Consult:

Once we understand your requirements, we will recommend the PHMTOOLS machinery that best suits your needs.

Free Quote:

We will provide a detailed quotation based on your inquiry, ensuring you receive the correct specifications, quality accessories and competitive prices.

Process Assessment:

Both parties will carefully evaluate and discuss all details of the order, including technical parameters, specifications and commercial terms, to eliminate any potential misunderstandings.

Ordering Now:

If you have no other questions, we will send you a proforma invoice (PI) and after your confirmation, we will proceed to sign the contract.

Production:

Once we receive the signed sales contract and deposit, we will immediately arrange the production of your product order. Production progress will be updated regularly throughout the manufacturing process.

QC:

The entire production process undergoes regular inspections and strict quality control measures. Our products are fully tested before shipping to ensure they operate seamlessly.

Shipping and Transportation:

After the buyer confirms, we will arrange delivery according to the terms stipulated in the contract.

Customs Clearance:

We will provide and deliver all necessary shipping documents to the buyer to ensure a smooth customs clearance process.

Support and Services:

PHMTOOLS is committed to providing professional technical support and free services through multiple channels such as phone, email, Skype, WhatsApp, real-time online chat, etc. Remote service is also available, and in selected areas, we offer on-site support.

Many buyers nowadays gravitate towards online shopping rather than the traditional offline method. During your online research and purchasing journey, several considerations should be taken into account as outlined above. This will guide you through an easily navigable buying process. You may opt for the convenience of local machinery stores, albeit at a higher cost, or choose the more cost-effective route of online purchasing directly from construction machinery manufacturers, securing direct services and support from the source. The decision ultimately hinges on your budgetary constraints and business requirements. In conclusion, finding what works best for your operations is paramount.

Should you have further inquiries, feel free to seek assistance. If you require any additional support, please let us know.

If our product has met your expectations or benefited your friend’s business, feel free to share the love! Relationships thrive on positive value exchange. Selfless sharing fosters collective growth. Thank you for being part of our journey.

Receive our monthly newsletter to stay current on all penghao innovations