The global construction industry relies on a diverse array of machinery to ensure efficiency, precision, and productivity. In this article, we’ll explore 14 common types of construction machines that are readily available on a global scale:

• Automatic stirrup bending machine

• Steel Pipe Polishing Machine

• Thread Rolling Machine

• Reducing Diameter Machine

• Straightening And Cutting Machine

• Wire Drawing Machine

• Manual Bending Machine And Cutting Machine

• Roll Cage Welding Machine

• Road Surface Construction Machine

• Transfer Pump

• Multi Blade Saw

• Fog Cannon Gun

• CNC Horizontal Lathe Machine

• Tower Crane

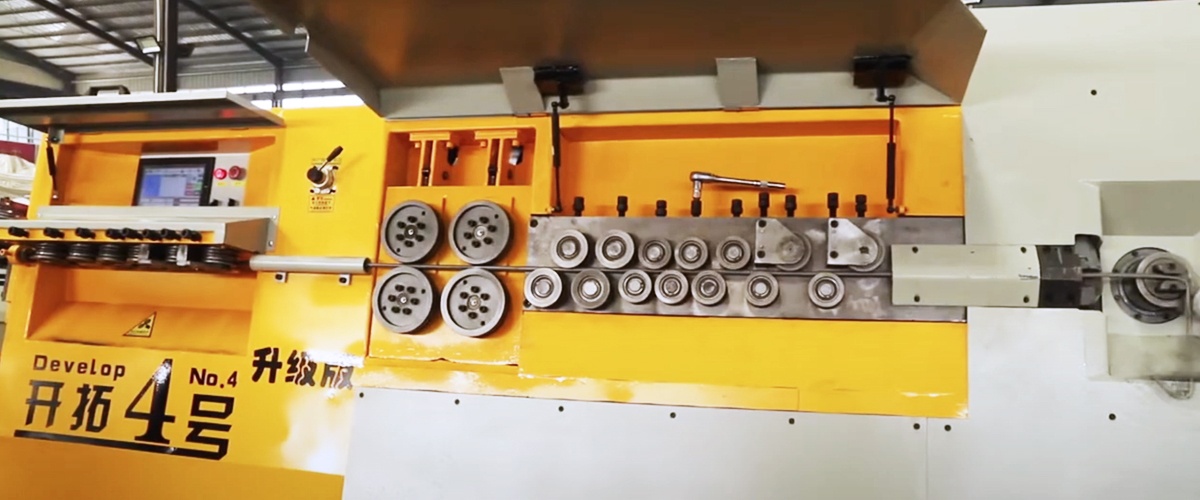

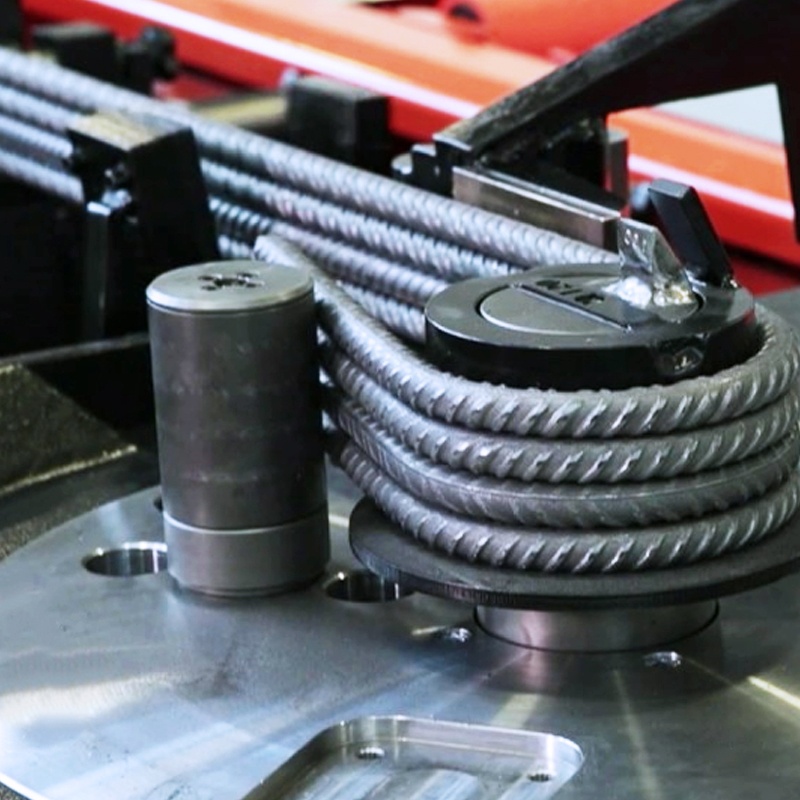

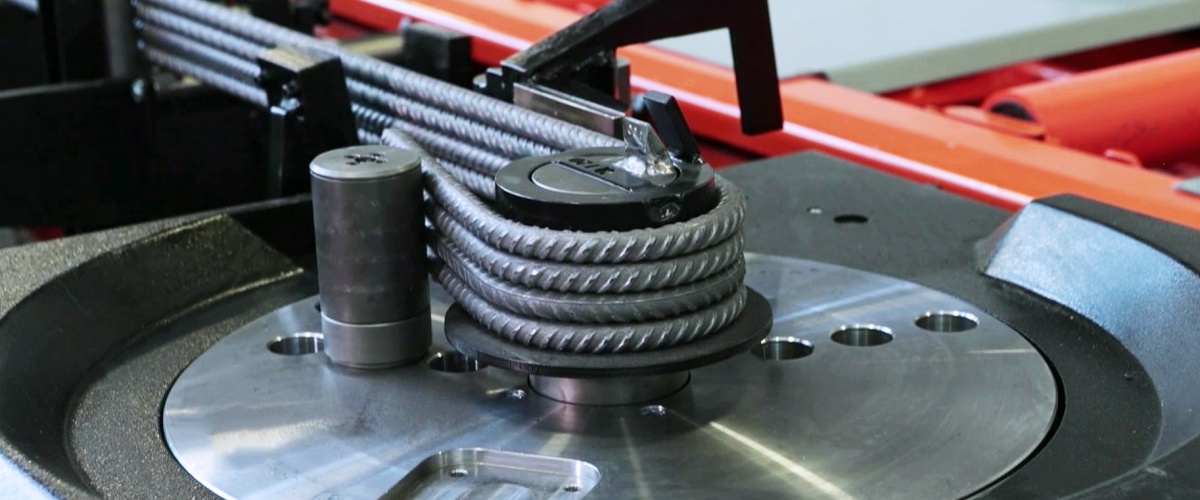

Automatic Stirrup Bending Machine:

Description: The Automatic Stirrup Bending Machine is a versatile equipment combining straightening, bending, and cutting functions. Widely used for processing steel into various shapes, it is renowned for efficiency, precise cutting, and rapid speed.

Steel Pipe Polishing Machine:

Description: This machine is designed for polishing steel pipes, ensuring a smooth and finished surface. It enhances the aesthetic appeal and quality of steel pipes used in construction projects.

Thread Rolling Machine:

Description: Thread Rolling Machines play a crucial role in processing threads on bolts, screws, and rods. They offer automatic feeding and radial or axial processing, contributing to efficient mass production.

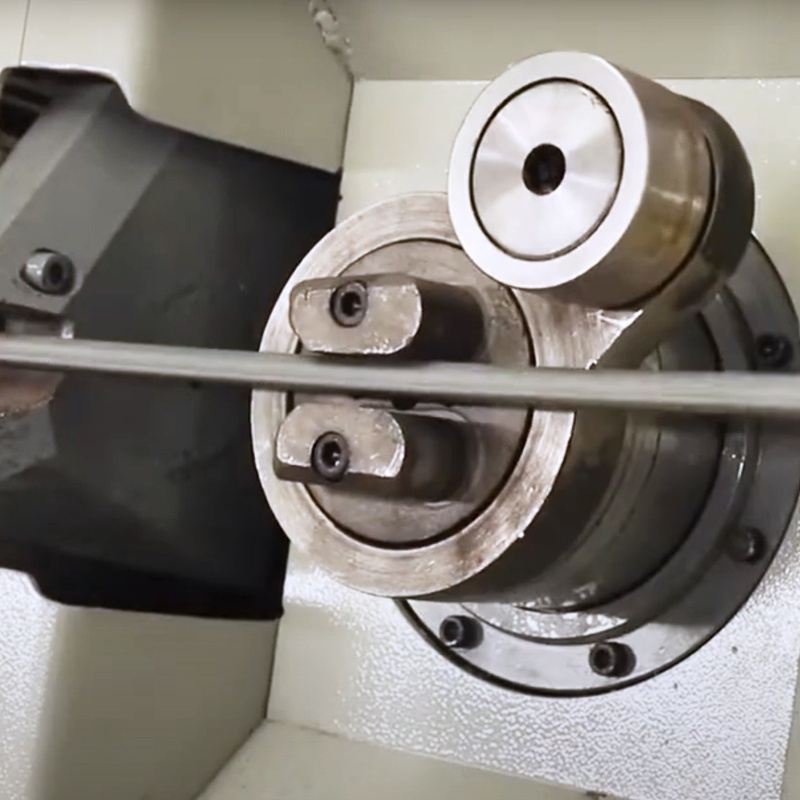

Reducing Diameter Machine:

Description: The Reducing Diameter Machine is a non-cutting processing machinery that efficiently compresses circular steel and threaded parts, improving material density and tensile strength.

Straightening And Cutting Machine:

Description: Featuring preset, automatic counting, and steel guiding functions, this machine is ideal for straightening and cutting steel, ensuring high-quality results in construction projects.

Wire Drawing Machine:

Description: Wire Drawing Machines are essential for reducing the diameter of metal wires, creating a smoother and more uniform surface. They find applications in various construction and manufacturing processes.

Manual Bending Machine And Cutting Machine:

Description: These manual machines provide flexibility in bending and cutting steel, allowing for precise customization based on construction project requirements.

Roll Cage Welding Machine:

Description: Roll Cage Welding Machines automate the process of welding roll cages, enhancing efficiency and precision in the construction of structural frameworks.

Road Surface Construction Machine:

Description: Road Surface Construction Machines are specialized equipment used in the construction and maintenance of roads, ensuring a smooth and durable surface.

Transfer Pump:

Description: Transfer Pumps are vital for moving fluids, such as concrete, from one location to another on construction sites, facilitating various construction processes.

Multi Blade Saw:

Description: Multi Blade Saws are powerful cutting tools used for efficient and precise cutting of materials, including wood, metal, and concrete, on construction sites.

Fog Cannon Gun:

Description: Fog Cannon Guns are employed for dust suppression on construction sites, enhancing safety and creating a healthier working environment.

CNC Horizontal Lathe Machine:

Description: CNC Horizontal Lathe Machines offer precision machining for various components used in construction projects, contributing to the overall quality of construction materials.

Tower Crane:

Description: Tower Cranes are iconic in the construction industry, providing heavy lifting capabilities for the placement of materials at great heights, making them essential for large-scale construction projects.

Conclusion:

These 14 types of construction machines represent a fraction of the diverse equipment available globally. From bending and cutting to polishing, welding, and lifting, each plays a crucial role in different stages of construction, ensuring projects are completed with efficiency, precision, and safety. When it comes to purchasing, choose the right type based on your business needs.