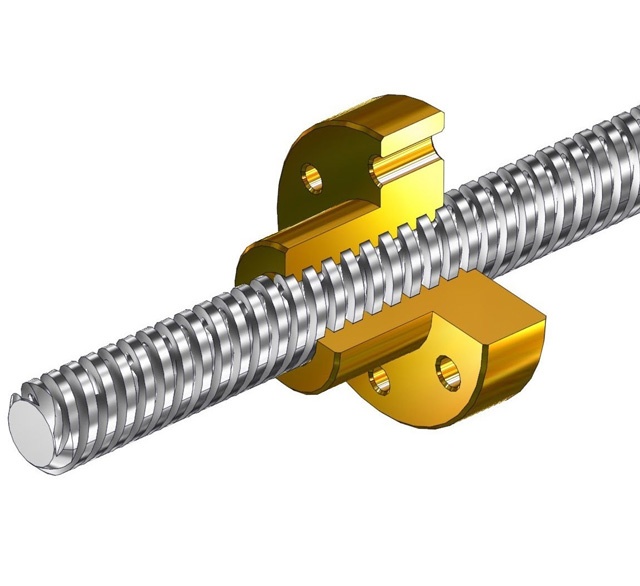

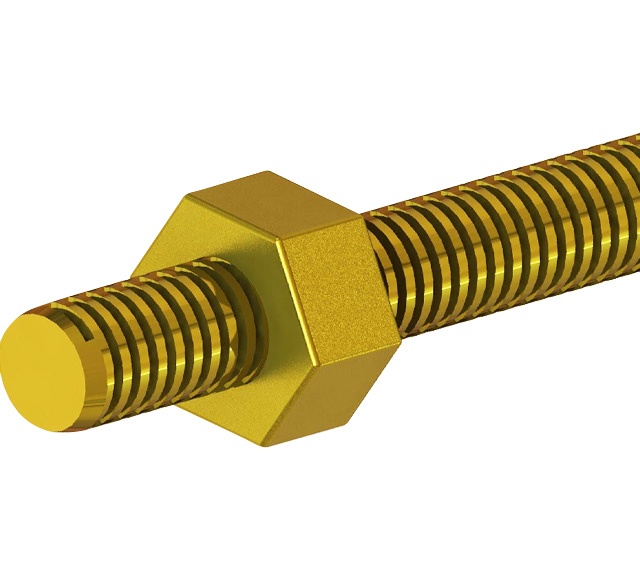

Our thread rolling machines are used for processing threads on bolts, screws, fasteners, threaded rods. Can be designed with automatic feeding device. It can perform radial or axial processing, and can process ordinary bolts, special bolts, tie rods, etc. with the corresponding rolling wheel.

Main Feature

1. The whole machine is cast as a whole, with solid structure, excellent workmanship, convenient maintenance and reasonable price.

2. It can be processed radially or axially, and can be used with corresponding rolling wheels to process ordinary bolts, special bolts, tie rods, etc.

3 The sliding parts are manually ground to improve processing accuracy.

4. Small size, high efficiency and low noise.

5. Use high-quality motors to make the machine more perfect.

6. The distribution box uses high-quality equipment and is cooled by high frequency to make the machine durable.

7 The timing gear adopts a hollow design, which no longer limits the screw length. Theoretically, the screw length is not limited.

8. This machine is suitable for metric threads and American threads.

9. The machine penetrates the workpiece into cold, twill and straight grain laminates; helical gears, helical knurled spline gears, straight bearings, necks and various formed bearings within the bearing pressure range.

10. It has safe and reliable electro-hydraulic execution and control functions, and each working cycle can choose manual, semi-automatic or fully automatic.

Our thread rolling machines can produce all types of cold formed threads in large and small batches in the most economical way. The normal base data for each type of machine listed in the table are not limiting values. Practical tests in the areas of manufacturing technology and material behavior constantly push the performance limits of our machines. Our growth depends on the ever-increasing knowledge of precision, which allows us to create custom designs for special applications, material properties, specific dimensions and mold shapes.

Robust construction enables deep thread forming, worm machining, grooving, knurling, rigidity and simplicity; hardened grade reduction and proper scrap slide, easy adjustment of machine and tools allow unskilled workers to operate the machine. The machine is ideal for mass production and optimal surface finish.