Client: Skyline Construction Co.

Challenge

Skyline Towers, a leading construction company, faced a daunting challenge with their latest high-rise project. The conventional method of manual rebar bending was proving to be a bottleneck in their construction timeline. The sheer scale of the project demanded a more efficient solution to meet tight deadlines and maintain optimal workflow.

Solution

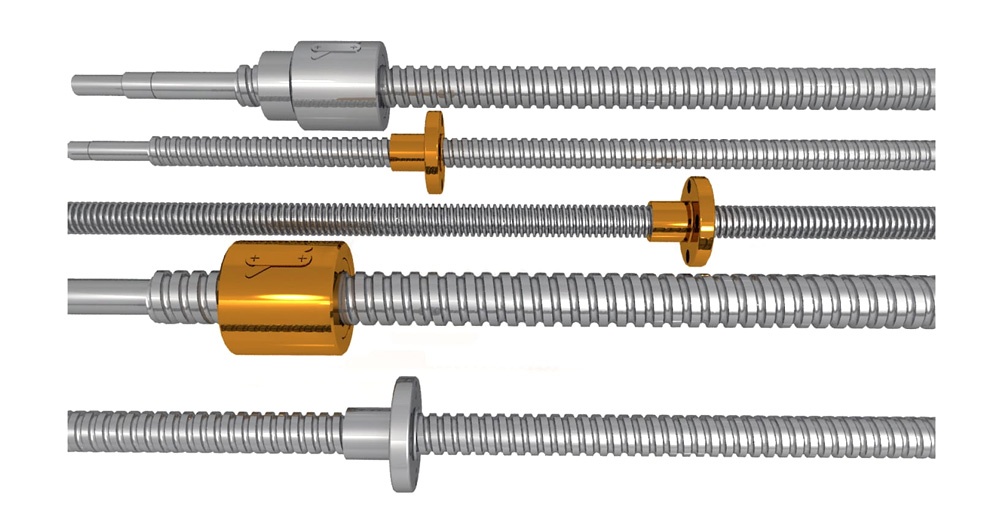

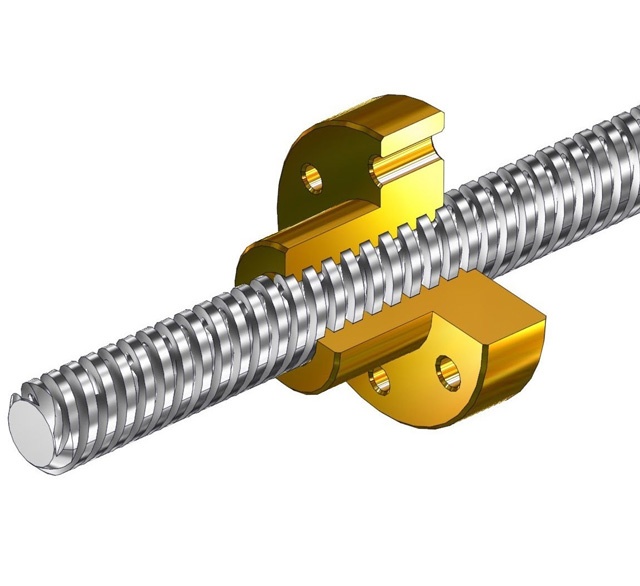

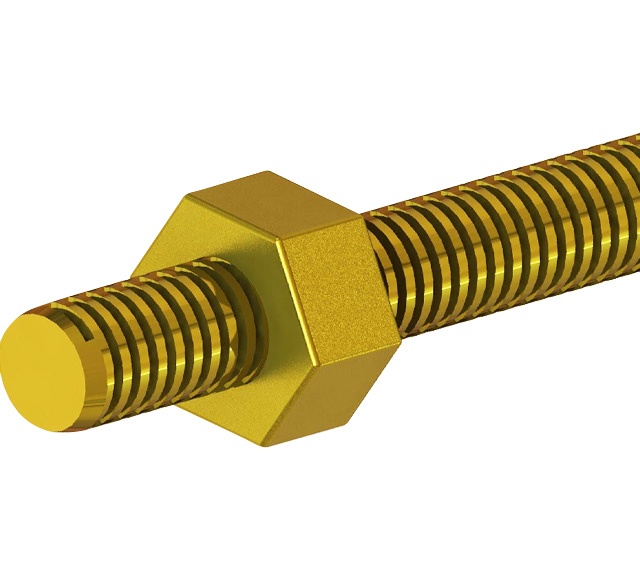

Understanding the urgency and scale of the project, Skyline Construction Co. turned to PHMTools for a solution. The implementation of the PHMTools Automatic Stirrup Bending Machine proved to be a game-changer. The machine’s advanced automation capabilities and precision in rebar bending were exactly what was needed to overcome the challenges posed by manual processes.

The PHMTools team worked closely with Skyline Towers to customize the machine according to the specific project requirements. The intuitive programming features of the machine allowed for seamless integration into Skyline’s existing construction workflow. The engineers and operators were trained to harness the full potential of the technology, ensuring a smooth transition.

Outcome

The impact was immediate and transformative. Skyline Towers not only met but exceeded their construction deadlines, completing the high-rise project well ahead of schedule. The efficiency gains were substantial, with a noticeable reduction in labor hours and associated costs. The accuracy of bends achieved by the Automatic Stirrup Bending Machine contributed to the structural integrity of the building, earning accolades for the quality of construction.

The success of this project established a long-term partnership between Skyline Construction Co. and PHMTools. The reliability and performance of the Automatic Stirrup Bending Machine became a benchmark for future construction projects, setting Skyline Towers apart in the industry for their commitment to innovation and efficiency.