Thread Rolling Machines For Automotive Manufacturing Projects

Our thread rolling machines are used for processing threads on bolts, screws, fasteners, threaded rods. Can be designed with automatic feeding device. It can perform

Are you in the process of selecting the right automatic thread rolling machine for creating precise threads in construction, metal fabrication, and manufacturing projects? Whether you’re associated with a construction company, a metal processing engineer, a manufacturing engineer, or a factory manager, whether you hold the position of a manager, quantity surveyor, plant manager, or dealer, PHMTOOLS, the globally recognized brand of automatic thread rolling machines, has meticulously curated a list of the most sought-after products in our 2024 Machine lineup.

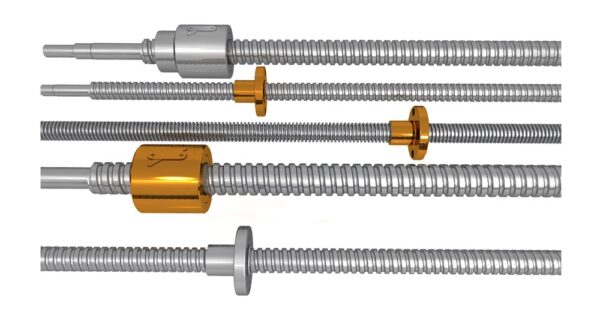

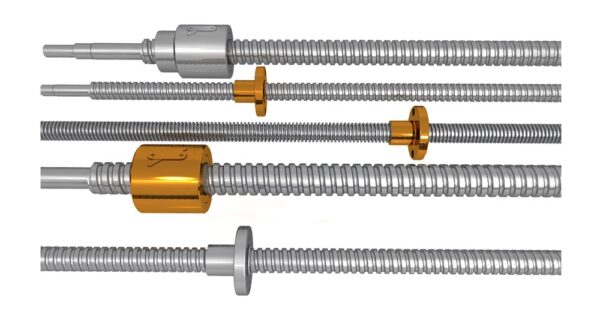

Our diverse selection caters to both novices and seasoned professionals, providing options for personal and commercial applications. Our thread rolling machines are used for processing threads on bolts, screws, fasteners, threaded rods. It can process ordinary bolts, special bolts, tie rods, etc. with the corresponding rolling wheel. Robust construction enables deep thread forming, worm machining, grooving, knurling, rigidity and simplicity. As a reputable manufacturer, supplier, dealer, and seller, PHMTOOLS not only delivers a range of top-quality machines but also provides expert support tailored to your needs.

Navigating through our selection is a breeze as we’ve streamlined the process for you. Simply compare features and costs to discover the optimal automatic thread rolling machine for your 2024 projects. Let’s embark on this journey together, ensuring precision and efficiency in your thread creation processes.

• Compact design and maintain high operating efficiency.

• Can adapt to various materials and thread specifications.

• Designed with user-friendly controls, it is easy to operate.

• Fast thread rolling process can be achieved.

• Made from durable materials and components for long life.

• Precision rolling capabilities for accurate and consistent thread patterns.

• Designed for heavy-duty applications.

• Equipped with advanced controls and features, offering enhanced customization options.

• Maintain energy efficiency and ensure optimal performance.

• Suitable for thread processing of various workpieces.

• Set up quickly and reduce downtime.

• Low maintenance with components designed for durability and minimal wear.

• Create high-quality threads with consistent accuracy.

• Equipped with automation features.

• Accommodates a variety of thread sizes and materials.

Our thread rolling machines are used for processing threads on bolts, screws, fasteners, threaded rods. Can be designed with automatic feeding device. It can perform

Why Choose China for Construction Processing Machinery Purchasing construction machinery from overseas markets brings a refreshing and high-quality experience and has the unique advantage of

The global construction industry relies on a diverse array of machinery to ensure efficiency, precision, and productivity. In this article, we’ll explore 14 common types

Thread rolling machines employ state-of-the-art technology and play a key role in various industries such as engineering construction projects, steel processing, fastener manufacturing, road construction, railway construction, construction site use, commercial use and industrial manufacturing. These machines enable fast thread rolling, create high-quality threads with consistent accuracy, and can accommodate a variety of materials and thread sizes, maintaining energy efficiency and ensuring optimal performance. Therefore it has become an integral part of modern manufacturing. They are widely used in industries where creating precise and reliable threads is critical to producing high-quality parts.

When considering purchasing a new thread rolling machine, there are several basic elements to consider, including the machine’s power output, size and type, material compatibility, and overall cost. Together, these factors help make an informed decision when choosing the right thread rolling machine.

PHMTOOLS is a trusted brand and a reliable source for your thread rolling machine expectations. This article provides a comprehensive guide for those looking for a thread rolling machine for hobby and industrial commercial use.

Now, let’s dive into the discussion.

A thread rolling machine is a specialized piece of equipment designed for the precise and efficient cold-forming of threads on cylindrical workpieces. Instead of cutting material, it deforms the workpiece to create the desired thread profile, resulting in stronger threads with improved surface finish.

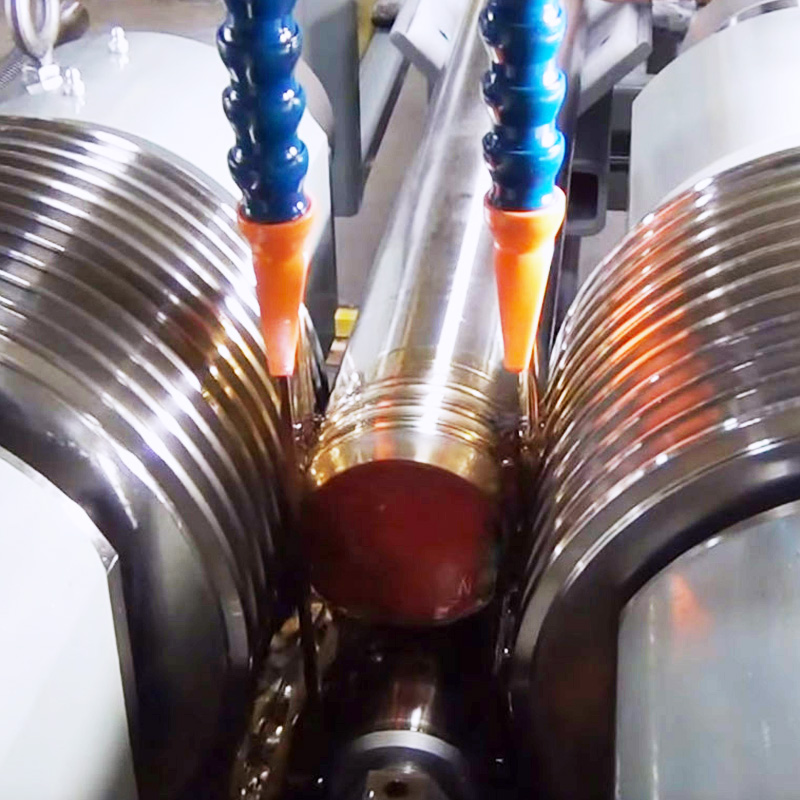

In essence, a thread rolling machine functions by pressing a rotating cylindrical workpiece between two dies with matching thread profiles. As the workpiece is compressed between the dies, the material undergoes plastic deformation, forming the threads on its surface. This cold-forming process is highly effective for creating threads on various materials, including metals.

Two-Axis Thread Rolling Machine:

A two-axis thread rolling machine utilizes two main axes for efficient and straightforward thread formation on cylindrical workpieces. This type is known for its simplicity, cost-effectiveness, and versatility in handling various thread types and sizes.

Three-Axis Thread Rolling Machine:

A three-axis thread rolling machine adds an extra axis for enhanced control and precision in the thread-forming process. It offers greater flexibility for intricate thread profiles, making it suitable for applications that demand higher precision and customization in threading operations.

Thread rolling machines find applications across various industries due to their versatility and efficiency. Some of the industries where thread rolling machines are commonly used include:

Construction: Used for threading bolts, screws, and other fasteners essential in construction projects.

Metalworking: Employed in creating threads on shafts, rods, and cylindrical components in metal fabrication and processing.

Manufacturing: Integral in the production of parts where precision threading is crucial for the performance and integrity of components.

Automotive: Utilized for threading automotive components, such as bolts, nuts, and other fasteners.

Aerospace: Applied in the aerospace industry for creating threads on critical components used in aircraft and spacecraft manufacturing.

Oil and Gas: Used for threading pipes, connectors, and other components in the oil and gas industry.

Electronics: Employed in creating threads on various electronic components and devices.

General Engineering: Widely used in diverse engineering applications requiring precise and strong threads.

The versatility of thread rolling machines makes them indispensable in many manufacturing and production settings where high-quality and efficient threading operations are essential.

1. The entire machine is fully cast with a robust structure, excellent technology, convenient maintenance, and a reasonable price.

2. It can be processed radially or axially and can be equipped with the corresponding rolling wheel to process ordinary bolts, special bolts, braces, etc.

3. The sliding parts, after manual grinding, enhance machining precision.

4. Small in size, efficient, with low noise levels.

5. Equipped with a high-quality motor, ensuring the machine’s perfection.

6. Power distribution box with high-quality equipment that, through high-frequency cooling, makes the machine durable.

7. Distribution gear with hollow design, no longer restricting the screw length; the screw length is theoretically unlimited.

8. This machine is suitable for metric and American threads.

9. The machine threads the workpiece in a cold environment, with straight, twill, and straight-grain rolling; helical gears, oblique rolling of splined gears can be straight within the range of bearing pressure, bearing, neck, and various forming bearings.

10. With safe and reliable electro-hydraulic execution and control functions, each working cycle can be selected between manual, semi-automatic, and fully automatic.

Machine Setup:

Ensure the thread rolling machine is securely placed and properly anchored.

Check and adjust the machine’s alignment if necessary.

Verify that all safety features are functional.

Die Installation:

Select the appropriate rolling dies based on the thread specifications.

Install and secure the dies onto the machine, ensuring proper alignment.

Workpiece Preparation:

Load the cylindrical workpiece onto the machine’s holding mechanism.

Securely clamp the workpiece to prevent movement during threading.

Adjustment of Machine Settings:

Set the machine parameters such as speed, pressure, and thread pitch according to the desired specifications.

Ensure that the machine is configured for radial or axial processing, as needed.

Initiate Rolling Process:

Start the thread rolling machine to begin the threading process.

Monitor the machine for any abnormal sounds or vibrations.

Inspection of Threads:

Once the threading process is complete, inspect the threads for accuracy, uniformity, and quality.

Make any necessary adjustments to the machine settings if deviations are observed.

Unloading the Workpiece:

Carefully remove the threaded workpiece from the machine.

Inspect the finished threads for any defects or imperfections.

Repeat or Change Over:

Depending on production requirements, repeat the threading process for additional workpieces.

If changing over to a different thread specification, follow the setup and adjustment procedures accordingly.

Shutdown and Maintenance:

Properly shut down the thread rolling machine following manufacturer guidelines.

Perform routine maintenance tasks, such as lubrication and inspection of components.

Check Die Alignment

Misalignment can affect thread quality.

Inspect Dies for Wear

Worn-out dies may need replacement.

Adjust Pressure and Speed

Improper settings can lead to threading issues.

Examine Workpiece Material

Ensure it’s suitable for cold-forming.

Regular maintenance and following manufacturer guidelines are crucial for optimal thread rolling machine performance.

Are you in the market for a reliable and efficient thread rolling machine? Look no further than PHMTools, a brand synonymous with excellence in thread rolling solutions. Here’s your comprehensive guide to making an informed purchase decision.

Construction Companies: Efficient processing of various bolts for construction projects.

Steel Processing Engineers: Versatile radial and axial processing capabilities for steel components.

Manufacturing Engineers: Precision threading for manufacturing applications.

Steel Plant Managers and Factory Managers: Durable construction and high-frequency cooling for sustained performance.

Fastener Manufacturers: Versatility in processing both ordinary and special bolts.

Construction Machinery Equipment Manufacturers: Suitable for diverse threading requirements in machinery production.

Distributors and Dealers: Varied rolling options, suitable for a wide range of customer needs.

Traders and Wholesalers: Compact size, efficiency, and competitive pricing for resale.

Consult:

Once we understand your requirements, we will recommend the PHMTOOLS machinery that best suits your needs.

Free Quote:

We will provide a detailed quotation based on your inquiry, ensuring you receive the correct specifications, quality accessories and competitive prices.

Process Assessment:

Both parties will carefully evaluate and discuss all details of the order, including technical parameters, specifications and commercial terms, to eliminate any potential misunderstandings.

Ordering Now:

If you have no other questions, we will send you a proforma invoice (PI) and after your confirmation, we will proceed to sign the contract.

Production:

Once we receive the signed sales contract and deposit, we will immediately arrange the production of your product order. Production progress will be updated regularly throughout the manufacturing process.

QC:

The entire production process undergoes regular inspections and strict quality control measures. Our products are fully tested before shipping to ensure they operate seamlessly.

Shipping and Transportation:

After the buyer confirms, we will arrange delivery according to the terms stipulated in the contract.

Customs Clearance:

We will provide and deliver all necessary shipping documents to the buyer to ensure a smooth customs clearance process.

Support and Services:

PHMTOOLS is committed to providing professional technical support and free services through multiple channels such as phone, email, Skype, WhatsApp, real-time online chat, etc. Remote service is also available, and in selected areas, we offer on-site support.

Pre-sale Service

1. Supply item design,process design.

2. Help you to chose the fitest machine.

3. Making the machine according to your requirement.

Sale Service

1. Acceptance equipment together with you .

2. Help you to make the method statement and the details of the process.

After Service

1. Guarantee for a year.

2. Quality problem,we will sent you the accessories.

3. Free repair whole using life(without the freight and accessories charge.

4. Send you the easy broken part of rebar stirrup bending machine for free.

Are you a factory?

Yes, we are. And we sincerely welcome to visit out factory at any time.

Do you have stock?

Yes, within 3 days the machine willl be delivered if you have no special need. But because of the air pollution problem. You need to make a decision as soon as possible. In case of the price of raw material is uping.

Is the machine easy to operate?

Yes, it is easy. Besides I will send videos to you, and let our engineer come to your country to help you if necessary.

If our product has met or exceeded your expectations, or if it has proven valuable to your friend’s business, we would be thrilled if you could help spread the positive vibes! Positive interactions form the bedrock of flourishing relationships. Through selfless sharing, we contribute to the growth of the community. Thank you for being a vital part of our journey.

Receive our monthly newsletter to stay current on all penghao innovations