Benefits Of Buying Construction Processing Machinery In China

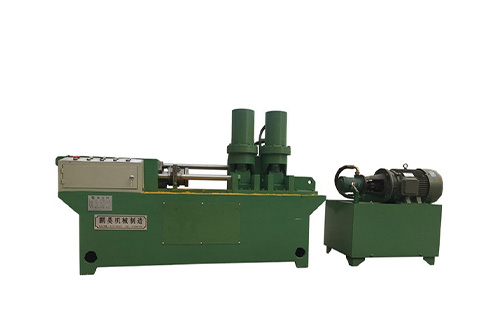

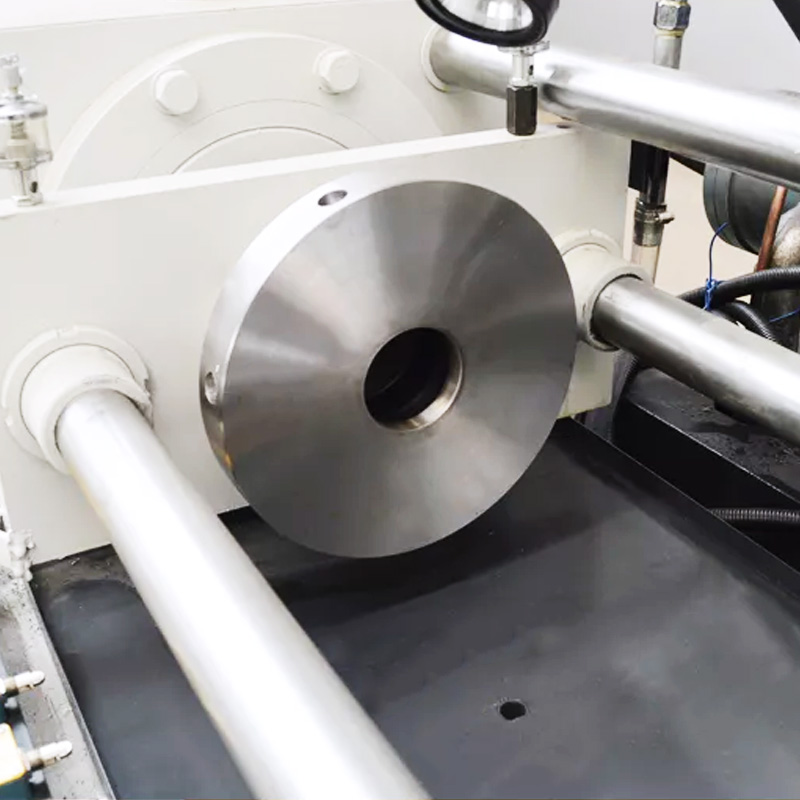

Why Choose China for Construction Processing Machinery Purchasing construction machinery from overseas markets brings a refreshing and high-quality experience and has the unique advantage of