In the realm of construction machinery, automatic stirrup bending machines play a pivotal role in reinforcing structures with precision and efficiency. As the demand for robust and reliable rebar processing solutions continues to grow, selecting the right steel rebar bender becomes paramount. This article aims to provide insights into the key considerations when choosing an automatic steel rebar bender, emphasizing the importance of tailored solutions for custom rebar processing needs.

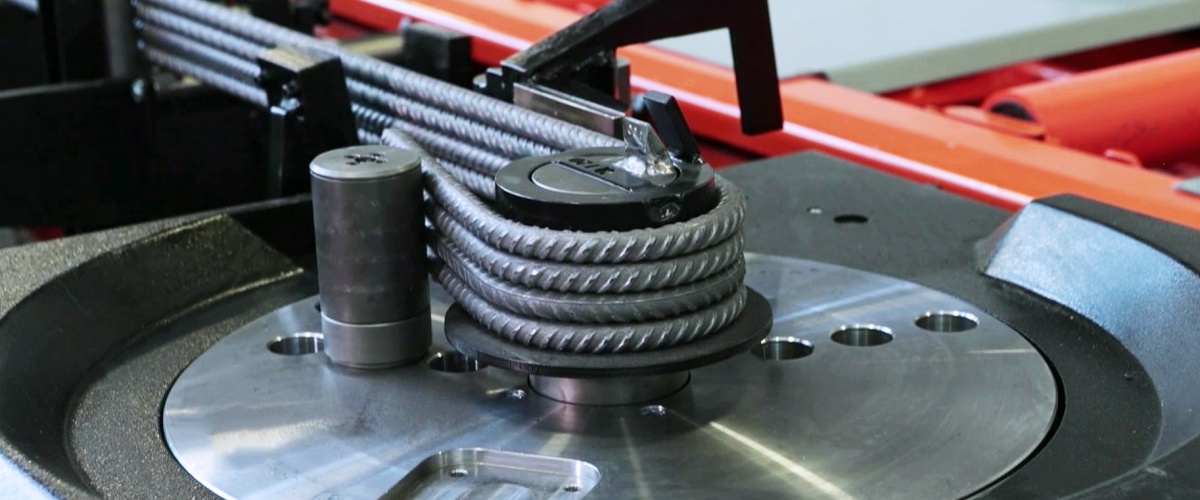

Capacity and Flexibility:

One of the first factors to consider is the machine’s capacity to handle different sizes and types of steel rebar. A versatile rebar bending equipment should accommodate a range of diameters and offer adjustable bending angles. This flexibility ensures compatibility with diverse construction projects, allowing for efficient processing of custom rebar shapes.

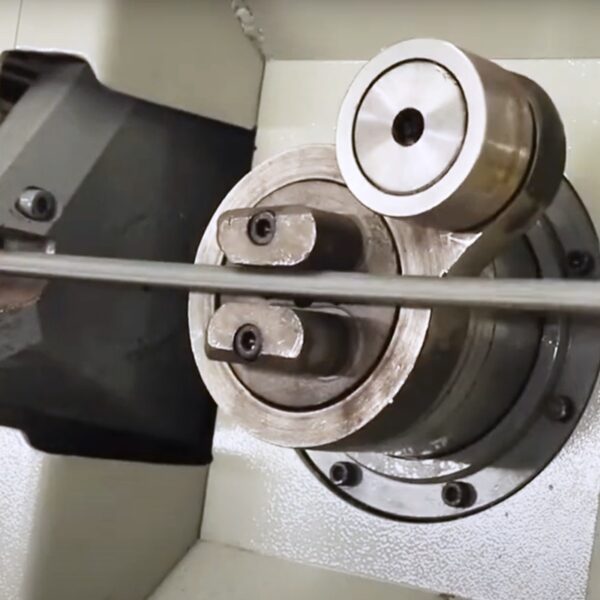

Automation and Precision:

The essence of an automatic steel rebar bender lies in its automation capabilities. Look for a machine equipped with advanced control systems that enable precise bending without manual intervention. Automation not only enhances accuracy but also boosts productivity by reducing human error and fatigue during prolonged operations.

Durability and Build Quality:

Construction sites demand robust and durable equipment that can withstand challenging working conditions. Assess the build quality of the rebar bending machine, considering factors such as the materials used, structural integrity, and resistance to wear and tear. Investing in a high-quality machine ensures longevity and minimizes the risk of breakdowns, contributing to overall cost-effectiveness.

Ease of Operation and Maintenance:

User-friendly interfaces and straightforward operational controls are crucial for optimizing workflow on construction sites. Additionally, a machine that is easy to maintain will contribute to its overall efficiency. Consider machines that come with clear manuals, accessible spare parts, and responsive customer support for swift issue resolution.

Custom Rebar Processing Solutions:

Every construction project has unique rebar requirements. Choosing a supplier that offers custom rebar processing solutions ensures that the automatic steel rebar bender can be tailored to meet specific project needs. Discussing customization options with the manufacturer or supplier will help ensure that the machine aligns perfectly with the demands of the project at hand.

Safety Features:

Safety is paramount in any construction environment. Look for a rebar bending machine that comes equipped with safety features such as emergency stop buttons, overload protection, and secure enclosures. Prioritize machines that comply with industry safety standards to mitigate risks and create a secure working environment.

Conclusion:

Selecting the right automatic steel rebar bender is a critical decision that directly impacts the efficiency and success of construction projects. By considering factors such as capacity, automation, durability, ease of operation, customization options, and safety features, construction professionals can make informed choices that align with their specific needs. Investing in a high-quality rebar bending machine ensures not only optimal performance but also contributes to the overall success and safety of construction endeavors.